Retool A2

Contents

Description

Retool A2 is a USB based tool head that works well with Recore. It has

- 1 TMC2209 stepper motor driver for an extruder

- 1 ADXL343 accelerometer for input shaping

- 1 Mosfet for a heater

- 1 Input for thermistor

- 3 Fan outputs with tach feedback

- 1 Peltier cooling output

- 1 inductive probe input

- 1 Neopixel output

- 2 End stop inputs

- USB-C with Power delivery, up to 24 V, 5 A.

It comes with Resend A2

- 24 V injector

- USB Power delivery

- Over current protection

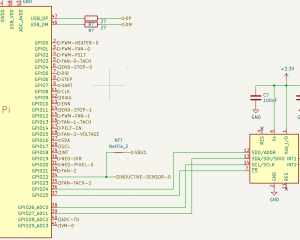

Shcematics

3D models

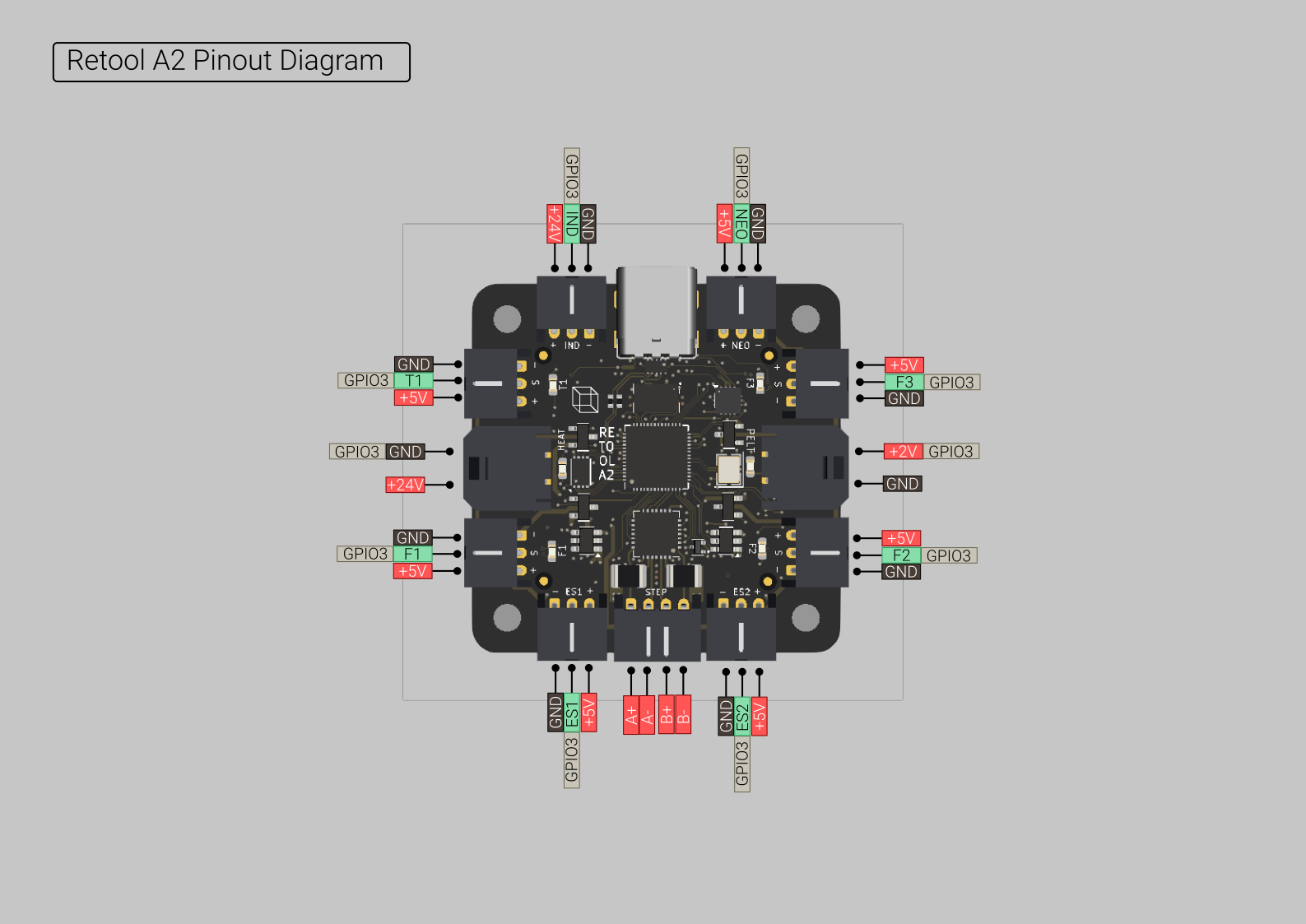

Pinout diagram

Pinout table

| Name | GPIO | Number | Name | GPIO | Number | Name | GPIO | Number |

|---|---|---|---|---|---|---|---|---|

| STEP | GPIO6 | 6 | END STOP 1 | GPIO4 | 4 | FAN 1 PWM | GPIO1 | 1 |

| DIR | GPIO5 | 5 | END STOP 2 | GPIO11 | 229 | FAN 2 PWM | GPIO12 | 12 |

| ENN | GPIO10 | 10 | NEOPIXEL | GPIO20 | 230 | FAN 3 PWM | GPIO21 | 21 |

| CLK | GPIO8 | 8 | NEOPIXEL DIR | GPIO19 | 231 | HEATER PWM | GPIO0 | 0 |

| DIAG | GPIO9 | 9 | PELTIER EN | GPIO14 | 232 | THERM 1 | GPIO28 | 28 |

| UART | GPIO7 | 9 | PELTIER V | GPIO2 | 233 | CURRENT MEASURE | GPIO29 | 29 |

| INDUCTIVE | GPIO19 | 19 |

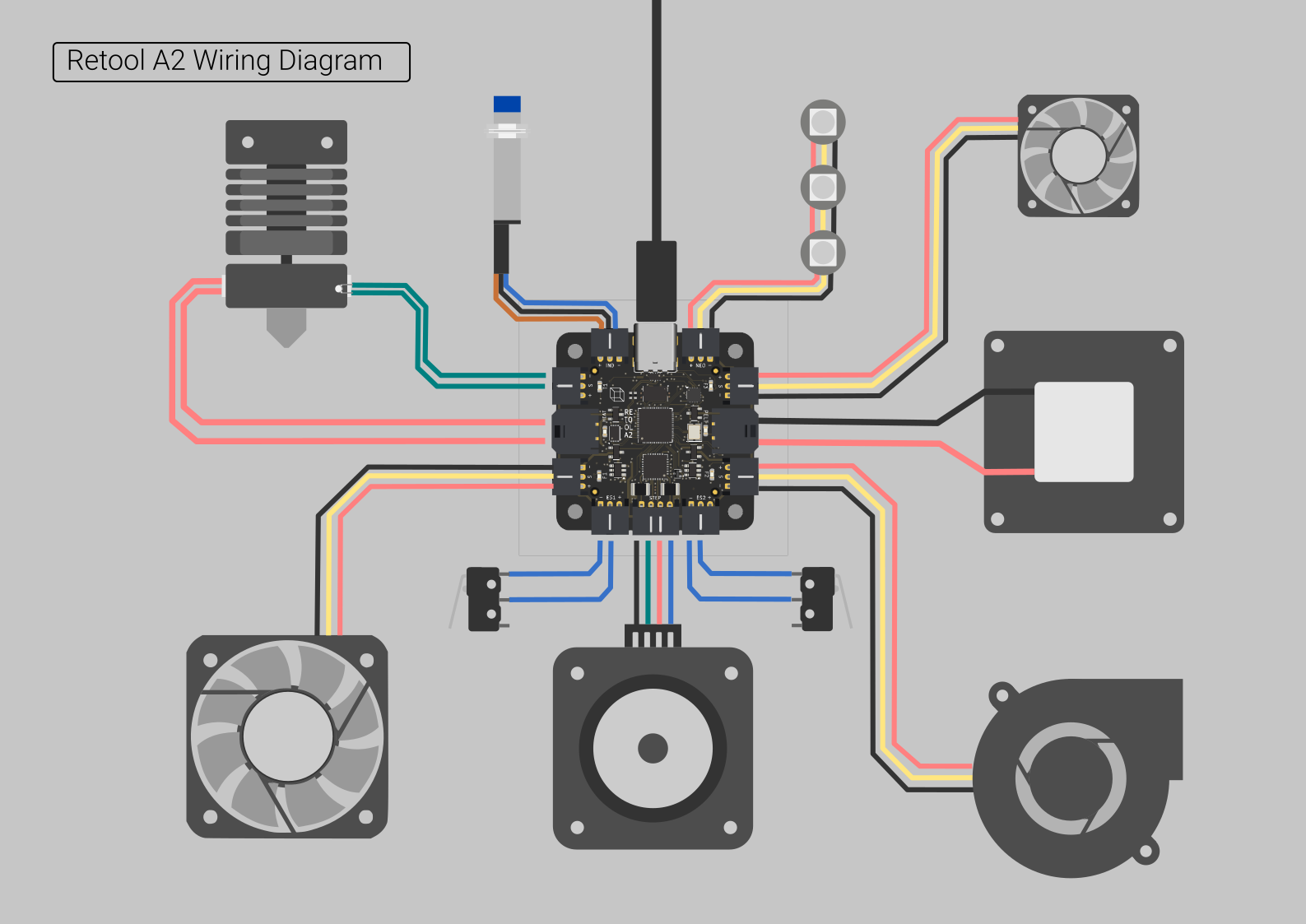

Wire diagram

Note about fan outputs: the middle pin is meant to be a tachometer input only. If you only have 2 wires, use only the pins labelled + and -.

3D model

3D model for using Retool A2 with Voron 2.4/Stealthburner https://www.printables.com/model/1190587-voron-24-retool-a2-holder

Klipper config

[mcu retool]

serial: /dev/serial/by-id/usb-Klipper_rp2040_E661AC8863905924-if00

[static_digital_output retool_led]

pins: retool:gpio2

[output_pin fan_r_1]

pin: retool:gpio1

[output_pin fan_r_2]

pin: retool:gpio12

[output_pin fan_r_3]

pin: retool:gpio21

[tmc2209 extruder3]

uart_pin: retool:gpio7

uart_address: 0

run_current: 0.500

hold_current: 0.500

sense_resistor: 0.1

stealthchop_threshold: 250

#endstop_pin: retool:gpio4

#enable_pin: !retool:gpio10

#rotation_distance: 40

#microsteps: 16

#position_endstop: 0

#position_max: 200

#homing_speed: 20.0

[extruder3]

step_pin: retool:gpio6

dir_pin: retool:gpio5

heater_pin: retool:gpio0

sensor_type: EPCOS 100K B57560G104F

sensor_pin: retool:gpio28

rotation_distance: 40

microsteps: 16

nozzle_diameter: 0.400

filament_diameter: 1.75

control: pid

pid_Kp: 22.2

pid_Ki: 1.08

pid_Kd: 114

min_extrude_temp: 30

min_temp: -272

max_temp: 300

[verify_heater extruder3]

check_gain_time: 2400

[adc_temperature retool_fan_current_0]

temperature1: 0

voltage1: 0

temperature2: 33

voltage2: 3.3

[temperature_sensor retool_fan_current_0]

adc_voltage: 3.3

sensor_pin: remote:gpio29

sensor_type: remote_fan_current_0

max_temp: 2.0

gcode_id: RemoteFanCurrent0

[adxl345]

cs_pin: remote:gpio25

spi_bus: spi1c

[resonance_tester]

accel_chip: adxl345

probe_points:

100, 100, 20 # an example

[probe]

pin: remote:gpio22

#--------------------------------------------------------------------

x_offset: 0

y_offset: 25.0

z_offset: 0

speed: 10.0

samples: 3

samples_result: median

sample_retract_dist: 3.0

samples_tolerance: 0.01

samples_tolerance_retries: 3

# Set this high to use GPIO20 as high frequency input

[static_digital_output Relit_direction]

pins: !remote:gpio19

[neopixel relit]

pin: remote:gpio20

chain_count: 12

[fan peltier]

pin: remote:gpio3

max_power: 0.1

cycle_time: 0.00001 #0.01

hardware_pwm: True

serial: /dev/serial/by-id/usb-Klipper_rp2040_E66368651B257D22-if00

[static_digital_output remote_led]

pins: remote:gpio2

[static_digital_output nepixel_dir]

pins: !remote:gpio19

[fan]

pin: remote:gpio21

tachometer_pin: remote:gpio23

cycle_time: 0.10

[fan_generic peltier]

pin: remote:gpio3

hardware_pwm: True

cycle_time: 0.000001

[heater_fan hotend_fan]

pin: remote:gpio1

heater: extruder

heater_temp: 50.0

[tmc2209 extruder]

uart_pin: remote:gpio7

uart_address: 0

run_current: 0.800

hold_current: 0.500

sense_resistor: 0.1

stealthchop_threshold: 0

[extruder]

step_pin: remote:gpio6

dir_pin: remote:gpio5

enable_pin: !remote:gpio10

heater_pin: remote:gpio0

sensor_type: ATC Semitec 104GT-2

sensor_pin: remote:gpio28

## Update value below when you perform extruder calibration

## If you ask for 100mm of filament, but in reality it is 98mm:

## rotation_distance = <previous_rotation_distance> * <actual_extrude_distance> / 100

## 22.6789511 is a good starting point

rotation_distance: 22.6789511 #Bondtech 5mm Drive Gears

gear_ratio: 50:10 #BMG Gear Ratio

microsteps: 16

nozzle_diameter: 0.800

filament_diameter: 1.75

control: pid

pid_Kp=28.278

pid_Ki=1.611

pid_Kd=124.070

min_extrude_temp: 15

min_temp: -273

max_temp: 500

pressure_advance: 0.03

## Default is 0.040, leave stock

pressure_advance_smooth_time: 0.040

[adc_temperature remote_current]

temperature1: 0

voltage1: 0

temperature2: 10

voltage2: 1.0

[temperature_sensor remote_current]

adc_voltage: 3.3

sensor_pin: remote:gpio29

sensor_type: remote_current

max_temp: 3.0

[temperature_sensor remote_mcu]

sensor_type: temperature_mcu

sensor_mcu: remote

[adxl345]

cs_pin: remote:gpio25

spi_bus: spi1c

[resonance_tester]

accel_chip: adxl345

probe_points:

125, 125, 20

[probe]

pin: remote:gpio4

x_offset: 0

y_offset: 25.0

z_offset: 0

speed: 10.0

samples: 3

samples_result: median

sample_retract_dist: 3.0

samples_tolerance: 0.01

samples_tolerance_retries: 3

[neopixel relit_head]

pin: remote:gpio20

chain_count: 4

initial_RED: 1.0

initial_GREEN: 1.0

initial_BLUE: 1.0

Firmware

Retool uses Klipper firmware. Make sure it matches the version on Recore. Resend has a custom firmware.

Klipper firmware compilation

The unit comes with firmware pre-installed. If you want to upgrade the firmware, these are the steps to reproduce. This can be done directly from Recore, or from a regular computer. If the device ID doesn't match, the board is not in DFU mode, and needs to be manually started that way. Use a paperclip or some wire, unplug the USB of the device, short the two round pads on the back of the PCB and plug in the USB. At that point the RP2040 will be in DFU mode, allowing it to be flashed.

cd /home/debian/klipper cp test/configs/rp2040.config .config make olddefconfig make -j make flash FLASH_DEVICE="2e8a:0003"

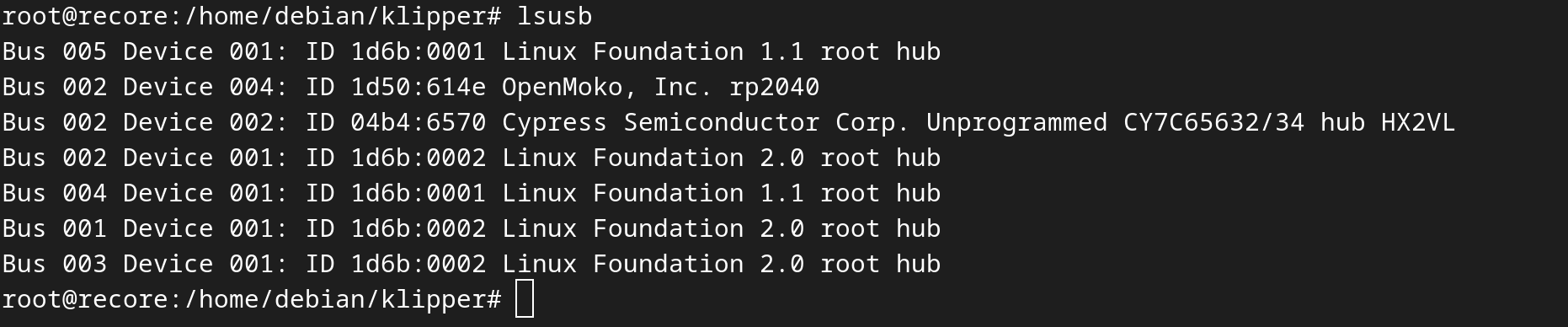

After that, the board should be visible as OpenMoko, Inc. rp2040

Enter boot mode from the command line

cd /home/debian/klipper/scripts

python3 -c 'import flash_usb as u; u.enter_bootloader("<DEVICE>")'

Entering bootloader on <DEVICE>

<DEVICE> is typically "/dev/ttyACM0" or similar.

Firmware for Resend

The Resend board has an ATTiny-1616-M. This MCU can be programmed with UPDI. A UPDI programmer can be made with a USB to TTY adapter and a 1K resistor between the Tx and the Rx pin.

To flash new firmware on Resend, use the following command from Linux:

avrdude -p t1616 -c serialupdi -P /dev/ttyUSB0 -b 57600 -U flash:w:simple.hex:i

The firmware is very simple for now. It enables the 24 V output without any checking at all. There is support for full USB Power Delivery capabilities, but this requires integration in Klipper, which is an upstream task.

Here is the firmware in .hex format. Named simple, because it does work, but bypasses some of the safety mechanisms (checking if the device on the other hand can tolerate 24 V). As long as you connect a Retool to the other end, it is OK.